-series-explosion-proof-power-distribution-panels.webp)

-x.webp)

-waterproof,-dustproof,-and-corrosion-resistant-lighting-(power)-distribution-box-(aluminum-alloy)-x.webp)

-x.webp)

-x.webp)

-x.webp)

-x.webp)

In industrial environments where explosive gases, dust, or volatile substances are present, electrical installations demand maximum safety and reliability. That’s where SEXESW explosion-proof junction boxes come into play—engineered to prevent sparks, contain internal explosions, and ensure uninterrupted electrical connectivity in the most hazardous zones.

From oil refineries to chemical plants, Shengyi EX’s explosion-proof enclosures are designed to resist corrosion, withstand extreme conditions, and comply with global safety standards. In this blog, we’ll dive into why explosion-proof junction boxes are critical, the key features that make SEXESW’s models superior, and where they are most effectively used.

Electrical connections in hazardous environments require more than just insulation—they need explosion containment. A standard explosion proof junction box can become an ignition source if sparks or high temperatures interact with flammable substances.

SEXESW’s explosion-proof junction boxes eliminate these dangers by:

✔ Containing Internal Explosions – With a reinforced, flameproof housing, SEXESW junction boxes prevent sparks or heat from escaping, keeping the surrounding area safe.

✔ Preventing Environmental Damage – Made from corrosion-resistant materials (cast aluminum, stainless steel, or reinforced fiberglass), they endure harsh conditions like chemical exposure, saltwater, and extreme temperatures.

✔ Meeting Global Certifications – Compliant with ATEX, IECEx, UL, and NEC standards, SEXESW ensures 100% adherence to international explosion-proof regulations.

By choosing SEXESW explosion-proof junction boxes, companies minimize downtime, enhance safety, and protect critical electrical systems in volatile settings.

Not all explosion-proof enclosures are built equally. SEXESW designs its devices to outperform competitors with these outstanding characteristics:

Explosion-proof sealing prevents gas or dust intrusion.

IP66/68 rated for superior water and dust resistance – ideal for marine, mining, and chemical industries.

Impact and vibration-resistant for heavy industrial settings.

Multiple entry options (cable glands, conduits, threaded ports).

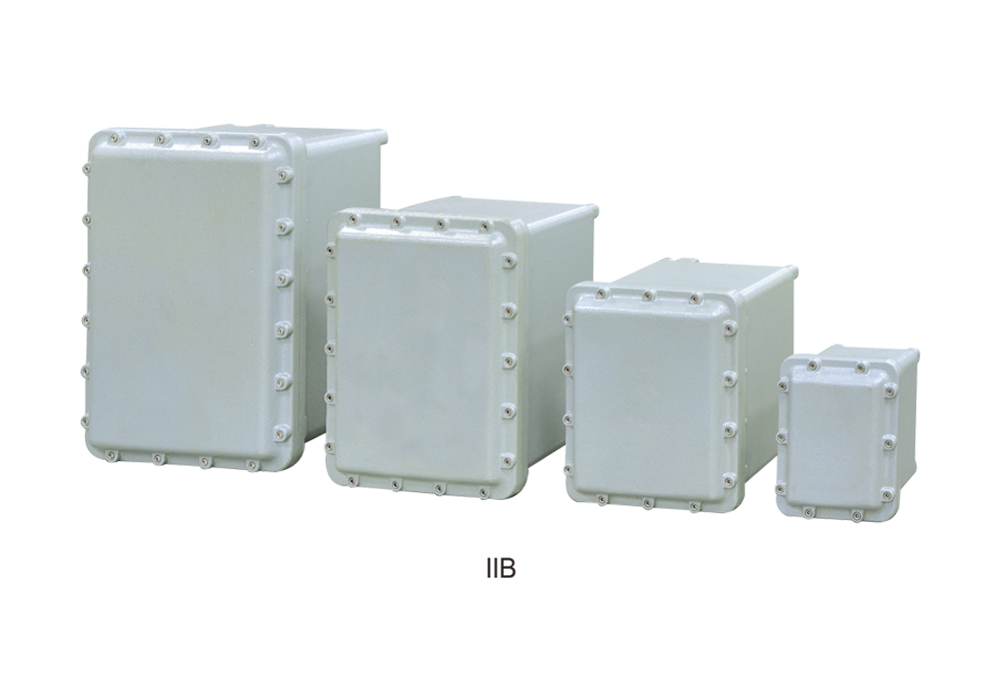

Wide range of sizes (from compact boxes to large multi-cable configurations).

Pre-drilled mounting points for quick and secure setup.

Spark-proof and non-conductive materials reduce fire risks.

Compatible with explosion-proof conduits, lighting, and switches for a fully protected electrical system.

SEXESW’s rugged, reliable, and certification-backed junction boxes ensure no compromises in safety, durability, or performance.

From offshore rigs to underground mines, these enclosures are crucial in high-risk electrical setups. Here are the industries that benefit most:

Drilling platforms and petrochemical facilities need flameproof electrical protection to prevent catastrophic failures.

Corrosive chemicals require stainless steel or fiberglass enclosures, which SEXESW delivers.

Dust-heavy environments require spark-proof electrical containment—SEXESW’s sealed junction boxes provide zero ignition risk.

Waterproof, salt-resistant enclosures keep electrical connections safe from corrosion and moisture.

By integrating Shengyi EX explosion-proof junction boxes, industries ensure uninterrupted operations, reduced fire hazards, and long-term equipment protection.

E-mail:

zou@shengyiex.com

Phone:

+86-13817799891

Add:

No.8 Bailian Road, Nanmingshan Street, Liandu District, Lishui City, Jiangsu Province